- The working principle and performance characteristics of pump traps

-

VMV Newton pump trap (Pump trap), also known as mechanical power pump. It uses the principle of traps, relying on steam, air and other gases as power to transport condensed water from the low pressure area to the high pressure area, or from the negative pressure area (vacuum) to the normal pressure area.The pump trap has a series of advantages such as automatic control, no cavitation, simple maintenance, no electricity, water hammer resistance, large displacement, explosion-proof, no noise, and the pressure of the power steam (gas) determines the head. It is unmatched by other pumps. . It is widely used in steam system condensed water, low viscosity and non-volatile liquid transportation.

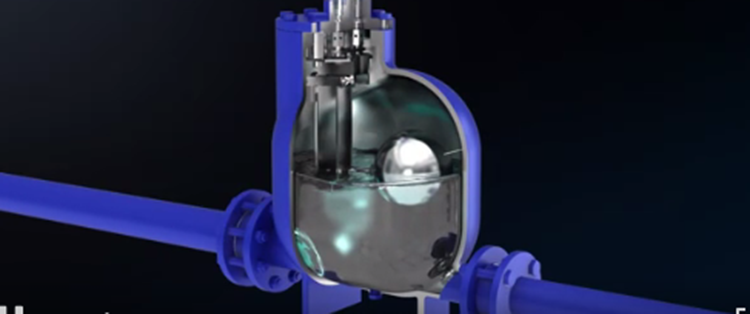

1. Working principle1) Inlet and exhaust steam (gas): At the beginning, the inlet check valve is opened, and the outlet check valve is closed due to the high back pressure. The valve begins to enter water, and the float is in a low position: as the water level rises, The exhaust valve will open, and the float reaches the highest controller and is in the switching zero state.2) Inlet steam (gas) drainage: the controller starts to switch at a high position and closes the exhaust valve: opens the power steam (air), injects steam into the valve, and pushes the condensate in the pump to the high pressure area under the push of steam pressure : At this time, the water inlet check valve cannot enter water due to the high pressure inside the valve. When the float reaches the low position, the controller switches to close the power steam, opens the exhaust valve, and enters the next action cycle.

2. Performance characteristics1) Non-electric drive, using steam or compressed air to drive, explosion-proof and safe, can be used in any environment.2) Compact structure, no requirements for installation, even in the open field does not affect its normal operation.3) Automatic control, the size of the water output is determined by the water intake. When the amount of condensed water increases, the working frequency speeds up, and when it decreases, the working frequency decreases, and it stops working when there is no condensed water.4) No cavitation work, completely overcome the shortcomings of electric pump cavitation.5) All stainless steel internal parts and special materials guarantee performance and life.

3. matters needing attention1) It is recommended that the head height of fluid entering is 0.5m or more (the pump cover is the reference), please refer to the "inlet water height correction factor".2) The power steam inlet is connected to RC1/2”.3) In order for the pump to operate normally, the saturated condensate needs to be flashed or condensed. The closed system must ensure the pressure difference and back pressure rate for the normal operation of the trap.4) The standard configuration of condensate inlet and outlet is HG/T20592-2009 PN16 flange connection. If other standards such as ASME16.5 and JIS are required, please specify.

3. matters needing attention1) It is recommended that the head height of fluid entering is 0.5m or more (the pump cover is the reference), please refer to the "inlet water height correction factor".2) The power steam inlet is connected to RC1/2”.3) In order for the pump to operate normally, the saturated condensate needs to be flashed or condensed. The closed system must ensure the pressure difference and back pressure rate for the normal operation of the trap.4) The standard configuration of condensate inlet and outlet is HG/T20592-2009 PN16 flange connection. If other standards such as ASME16.5 and JIS are required, please specify.

Professional in Bellows Seal Valve Manufacturer | Since 1998