There is a warm applause from Newton’s training room. It is the second employee training session of this month. The lecturer of the conference is Han Jianping. Mr. Han was engaged in valve production and quality management for more than 30 years. In the free time, Mr. Han shares some of the problems encountered in the usual work. In order to encourage this willingness to share, learn and improve. After the company coordinated the organization, it formed a staff training session twice every month. Lecturer Mr. Han shared his accumulated experience and management requirements with everyone. For example, the acceptance of rough castings, the cast need to be clear, the valve body surface should be smooth, sand holes and pores and other defects need to be eliminated, the valve body wall thickness and size should have sufficient margin. The detailed description is complemented by picture descriptions, making the acceptance criteria clear.

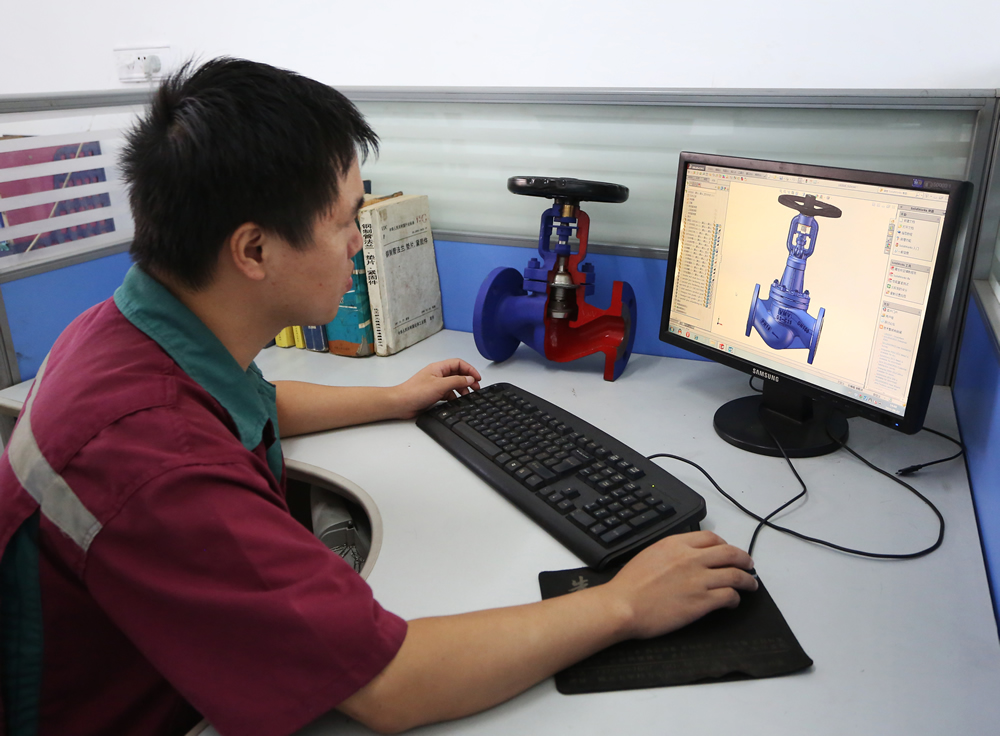

Chen Guohao came to the Newton team for half a year and was influenced by the atmosphere of learning and sharing. He also used his leisure time to learn. Combine the theoretical knowledge in the university with the actual production. The familiarity and application of the cloud platform management system make the production become data, the inventory quantity of the raw materials, the product specifications and quantity in the production process, and the inventory quantity of the finished product in warehouse become clear. Then arrange the production plan according to the order situation. Continuously improve the supplier system and screen all suppliers. Select a supplier system with high degree of cooperation, good quality, fast delivery, and favorable price. Strengthen Newton's competitiveness.

Products Category

- Bellows Seal Globe Valve

- Bellows Seal Gate Valve

- Globe Valve

- Gate Valve

- Check valve

- Strainer

- Relief Valve

- Steam Trap

- Control Valve

Contact

Tel: +86-577-67978269

Fax: +86-577-67376711

E-mail: vmv@bellowvalves.com